ENDER 3 PRO – PETG ISSUE – EXTRUDER CLICKS AND PETG WORN DOWN BY EXTRUDER [SOLVED]

So this is she was a tricky one your extruder starts to click but the PETG still prints for a while. If it goes on long enough your PETG will stop printing all together and jam in the nozzle

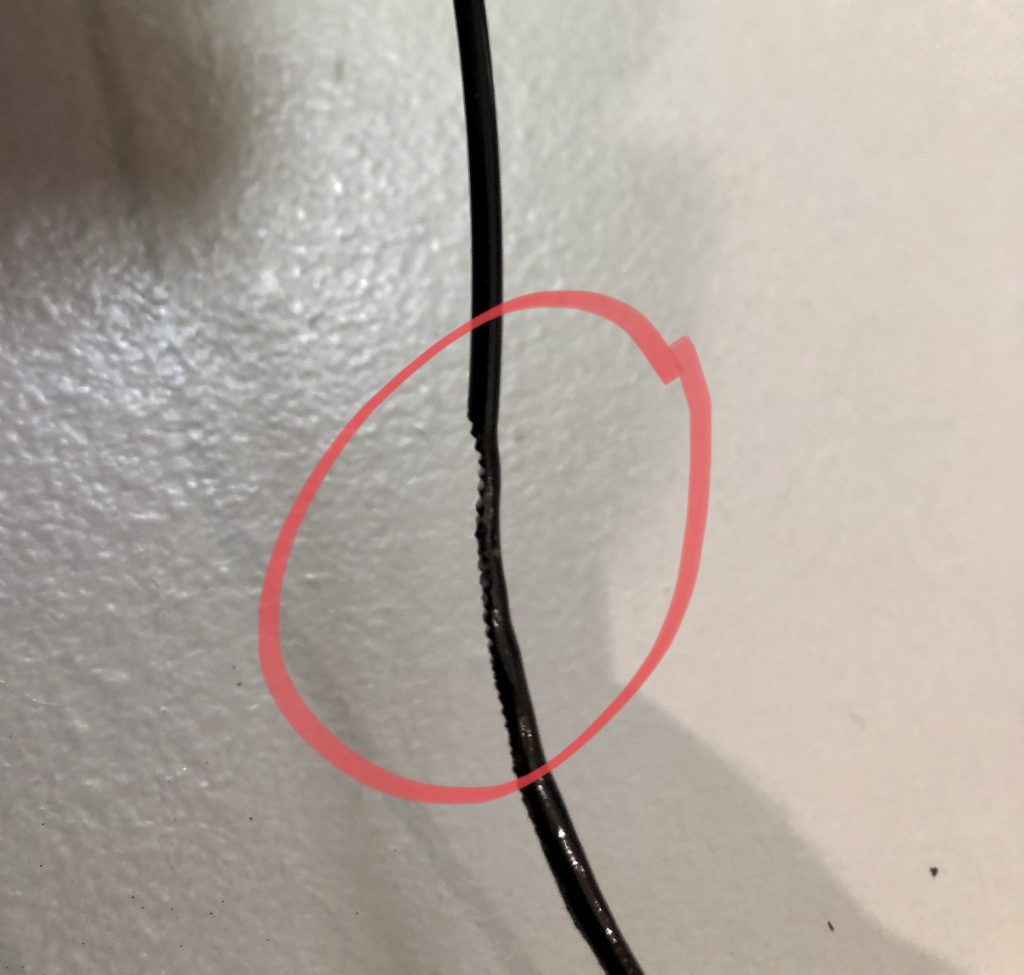

When you clear the jam by pulling the PETG out and you look at the hot end part of it, it’s melted and thicker than the rest of the filament.

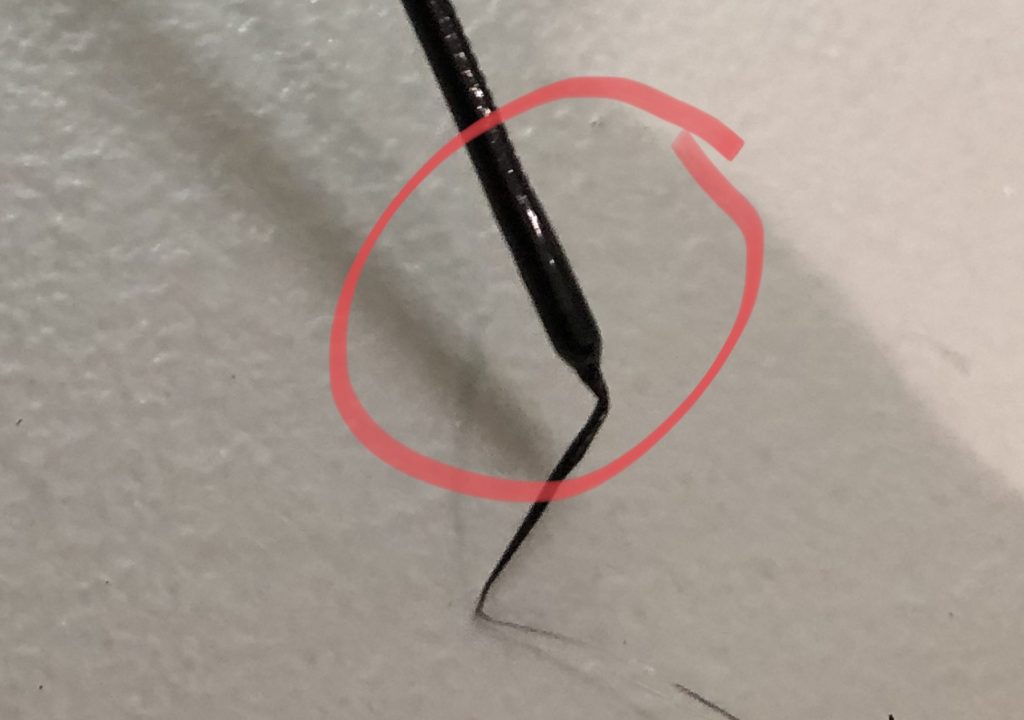

When you look at the filament where it was stuck in the extruder it’s substantially worn down and sometimes it’s completely broken off

Essentially what’s happening here is you are putting too much filament through the extruder and it’s backing up at the hot end. Once it backs up too much it jams the nozzle in your extruder starts clicking and wearing down the filament all the way to the point where the filament will break off

The fix for this is easy slow down the amount of filament you are putting through the extruder and that will solve the issue. PETG cannot print as fast as PLA so you will need to put new settings in for the print speed field in your slicer.

I have found that printing somewhere between 1800 to 2200 mm/min is the sweet spot for my under three pro running Amazon basics PETG black. However this setting will change depending on the manufacturer you use and the color and the density of the filament as well.