ENDER 3 PRO – UNDER EXTRUSION ISSUE [SOLVED]

To fine tune your Ender 3 Pro you will need to measure the amount of filament that is passing through the machine using the following test, to ensure your settings are correct

First you going to want to disconnect your hotend from the extruder, and place these in an area where you can heat them up and they will not damage themselves or anything around them.

Next you’re going to want to go into the settings of your Ender 3 and click on preheat PLA. This will warm up the hot end and allow you to extrude for our test

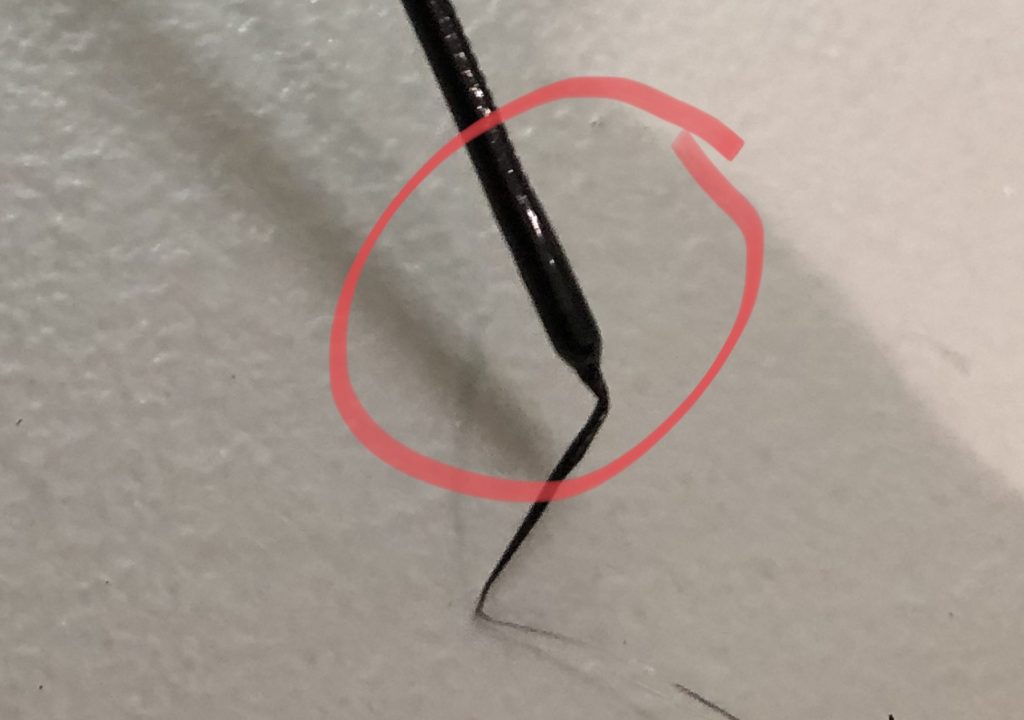

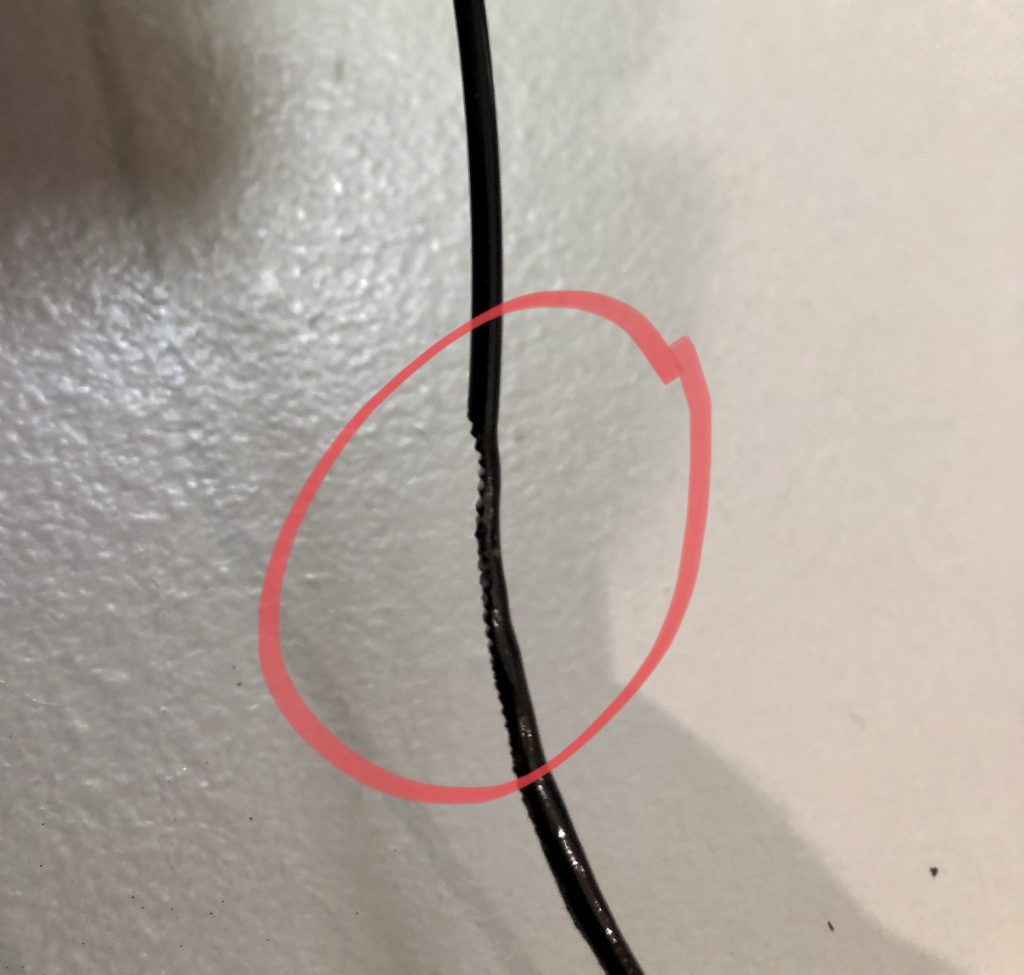

Measure out 120mm from entry point on extruder to the spool, and mark it on the filament using a notch or a marker (I prefer a slight notch)

Open Octopi

Go to Terminal Tab

Enter in the following code

G1 E100 F100

Press Send

This will extrude 100mm of filament

Now measure the difference of what went in, verses what is left.

I extruded 90.5mm instead of 100mm, and have 29.5mm left before my notch

Back in Octopi

Terminal Tab

Enter in the following code

M503

Press Send

Search for M92 line and verify it says E93

This is what you will edit

To figure out the new value for E93 do the following

100/90.5*93=102.76

E93 should be E102.76

The values above translate to this

100 – Distance that should have been extruded

/ – divided by

90.5 – is the distance that was extruded

* – Multiplied by

93 – This is the E93 value we saw earlier

Back to Octopi Terminal Tab

Enter in the following

M92 E102.76

Press Send

Enter in the following

M500

Press Send

Your new settings are saved, and your extrusion will be accurate. Feel free to repeat the above steps to ensure your settings are correct and the extrusion works as expected